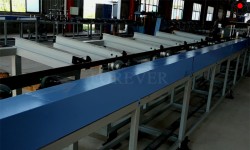

Heating Furnace Before Slab Forging

Features:

1.Application:Heat Treatment for Slab,Billet,Steel wire,Shaft,Bearing,Guide rail,Leaf spring,Spring

2.Available Power:100KW-10000KW

3.Non-standard Product:Professional Customization

Product Detail

Application Video

Product Tags

Forever Furnace devotes itself to designing and manufacturing heating furnace before slab forging for more than 16 years. Our heating furnace before slab forging is non-standard product.The user only need to tell us the slab specification, heating temperature and production capacity,then we will give you the best offer and solutions!

Technical Parameters for Heating Furnace Before Slab Forging:

(1)Slab size:5000mm(Length)*90mm(Width)*90mm(Thickness)

(2)The maximum transmission speed is 15m/min;the speed regulation range is 9-15 m/min.The steel billet speed is constant.

(3)Temperature distribution:

A: The feature of slab section temperature distribution:the billet core temperature is 1100℃;the surface temperature is 800℃. The temperature need to raise by 300℃.

B: The feature of billet head and tail temperature distribution:the head temperature is 50℃ higher than tail temperature.

Application for Heating Furnace Before Slab Forging

Mainly for hardening of shaft (direct axis, camshaft, crankshaft, gear shaft, etc.); gear, sets, ring, disc type; silk machine machinery; surface heat treatment of guide, plane and a variety of mechanical automobile and motorcycle parts.

Specialized in manufacturing induction heat treatment furnace since 1999, Forever Furnace will be very glad to be your business partner in the field of heating furnace before slab forging!

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.